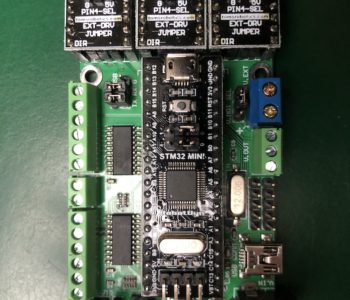

CNC

CNC

Router Hacking

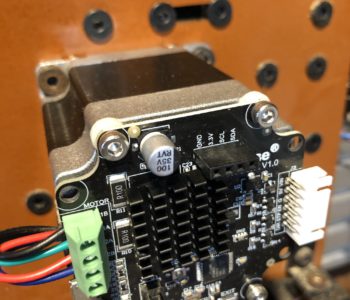

In starting the Quarinjection project, I knew that it involved some custom fabrication of brackets, covers, etc. One of my existing skills and resources was a small CNC router that I built a few years ago from an Openbuilds OX design. Ideally I could CNC some aluminum parts. It’s perfectly capable of cutting aluminum, it’s just a trickier material than wood.

The problem: The spindle I have is a 1hp Bosch Colt PR20EVS router. The Colt works well for routing wood but aluminum requires a much lower spindle speeds. The stock Colt router runs 16K-35K RPM. Too high a surface speed (speed of the flute through the material) to cut chips and not just stir weld the aluminum (which I did a lot of trying to get this to work). I needed a maximum minimum(?) speed of around 10K RPM to achieve a surface speed of ~350ft/min with an 1/8″ bit. (The ideal speed for 6061 Aluminum is about 280SFM)

The Colt has a built in speed controller (via a thumb dial at the top) which I figured I could modify to lower the minimum speed without making it unusable. The motor is a 110v AC brushed which have limited torque ranges, so I’d be sacrificing a bit of torque at lower speed.

I measured the speed before taking it apart. (I’m measuring off of the collet nut, but one flat is painted white).

Maximum was also lower than the spec at ~30K.

Surgery!

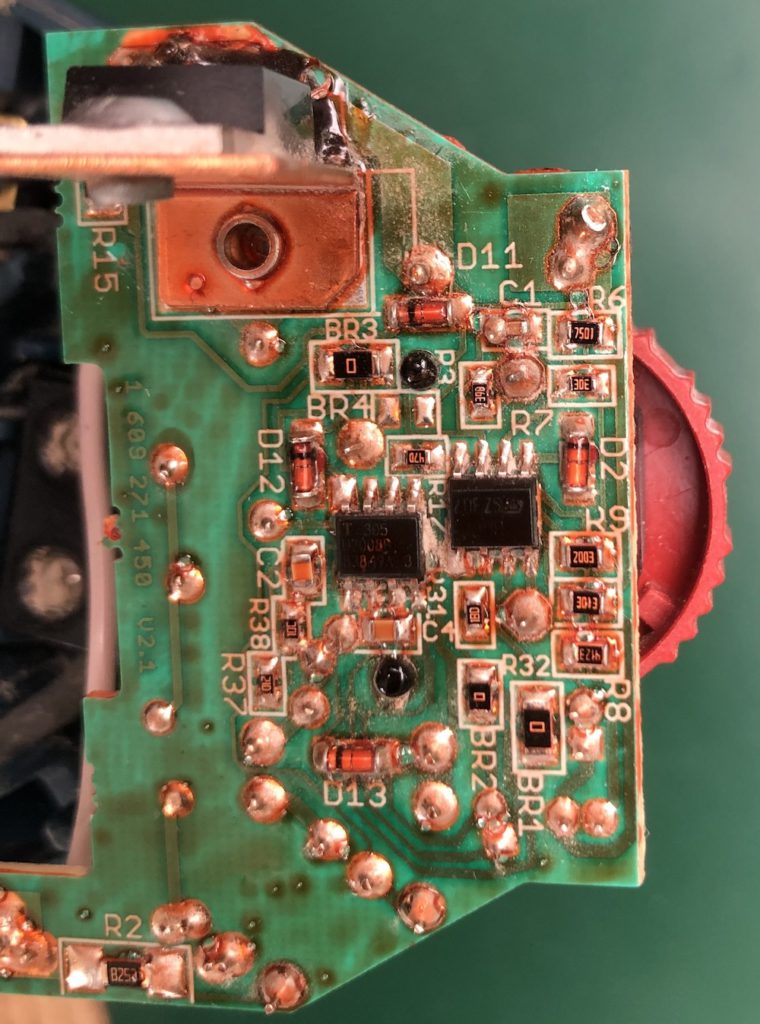

I was never able to identify the other chip, but my guess is some sort of opamp.

Time for a bit of reverse engineering… luckily a simple single sided board which was not buried in potting compound. The core of the speed control is an Atmel U2008B – Low Cost AC Phase Controller. The chip is the one on the left in the picture above. This manages speed via phase shift and provides soft start and some load correction (so as the router gets loaded the RPM stays the same). The large Triac on the heat sink at the top of the board does the load switching.

The Red thumb wheel, a 2.5Kohm rheostat, is in series with a base resistor R7, which measures 2.5Kohm. Setting 1 is 5K=13000RPM, and setting 6 is 2.5K=30000RPM.

The marking on the SMD resistor of 398 threw me for a while (3900MOhm?), but this is a EIA-96 coded resistor sloppily marked 39D=2.49K. These resistors are 0603 sized (6mm x 3mm) which is hard to show just how tiny this is (think grain of pepper sized). Resistor assortments are available and inexpensive ($0.01/ea)

Minimum speed was at 5K total resistance, maximum at 2.5K so an increase in resistance would reduce the overall speed. Replacing R7 with the next stock value of 3.3K (EIA-96 51D) for a total resistance of 6.3K. This should give me a 25% (6.3K/5K) reduction in speed overall or 10,400K RPM minimum (assuming it’s roughly linear). To jump to the next value (5.1K) that I had on hand meant the adjustable range would get too low.

A bit of finicky soldering later…

Success! The router doesn’t seem to be bothered by the change and runs normally at the lower speed. Off to cut aluminum!

Afterthought: I will eventually buy a true CNC spindle for this rather than mucking around with modifying a router, but for $8 I was able to get this to work.